Seemingly insurmountable challenges for electric- and hydrogen-powered bikes mean synthetic e-fuel is looking increasingly attractive

Electric car sales are increasing rapidly and the latest models’ large batteries and fast-charging abilities eliminate concerns about range anxiety, but we’ve yet to see anything comparable in the motorcycle market as manufacturers continue to wrestle to create EV two-wheelers that are better than the existing petrol-powered machines.

And that’s the key to success. The recent boom in electric car sales might be partially encouraged by tax breaks or the prospect of lower running costs, but the real tipping point that’s drawing customers in their direction is the fact they’re now better than combustion engine vehicles in many ways. Instant torque, plentiful power, unbeatable smoothness and increasingly affordable pricing means that for many drivers they’ve become the logical choice rather than the eco-friendly statement that they once represented.

E-fuel: could it be the saviour with its multitude of production and storage benefits?

But on two wheels the tipping point at which a battery-electric model becomes more tempting than a conventional ICE machine still seems far over the horizon. Sure, battery power makes sense for inner-city commuter bikes with no need for high-speed or long-distance ability, but as soon as must-haves like speed, range and handling are thrown into the mix the electric options diminish to the point of non-existence.

It comes down to a question of energy density. The lithium-ion battery pack needed to give a Tesla Model S a real-world range of around 500km weighs more than 500kg. In comparison, a similar-sized car achieving an unimpressive 10L/100km would need 50 litres of petrol – about 40kg-worth – to manage the same range.

A company called Synhelion will open the world’s first industrial solar fuel plant

In a car, the extra weight can be tucked away. Electric motors, lighter and smaller than combustion engines, help offset the mass, the vast size of the batteries can be hidden underneath the floor, and in a vehicle weighing north of two tonnes a few hundred extra kilos makes little difference.

Bikes, particularly high-performance ones, couldn’t be more different. Their engines are already designed to be as light as possible and a typical 15 litres of petrol only weighs around 12kg. Packaged in a compact, lightweight tank, that fuel contains many times more energy than you could hope to find in any battery of a comparable size and weight. Even with a relatively inefficient internal combustion engine the ICE-powered bike will go much faster and much further.

Yes, battery technology is certainly improving, but at the current rate, it will still be decades before a battery can hope to come close to the energy density of petrol.

Carbon neutrality’s the goal

Sustainability matters

Just because battery-powered electric bikes aren’t likely to match ICE equivalents in performance and weight for years, doesn’t mean we can simply continue to burn fossil fuels unbridled. That’s where e-fuel comes in.

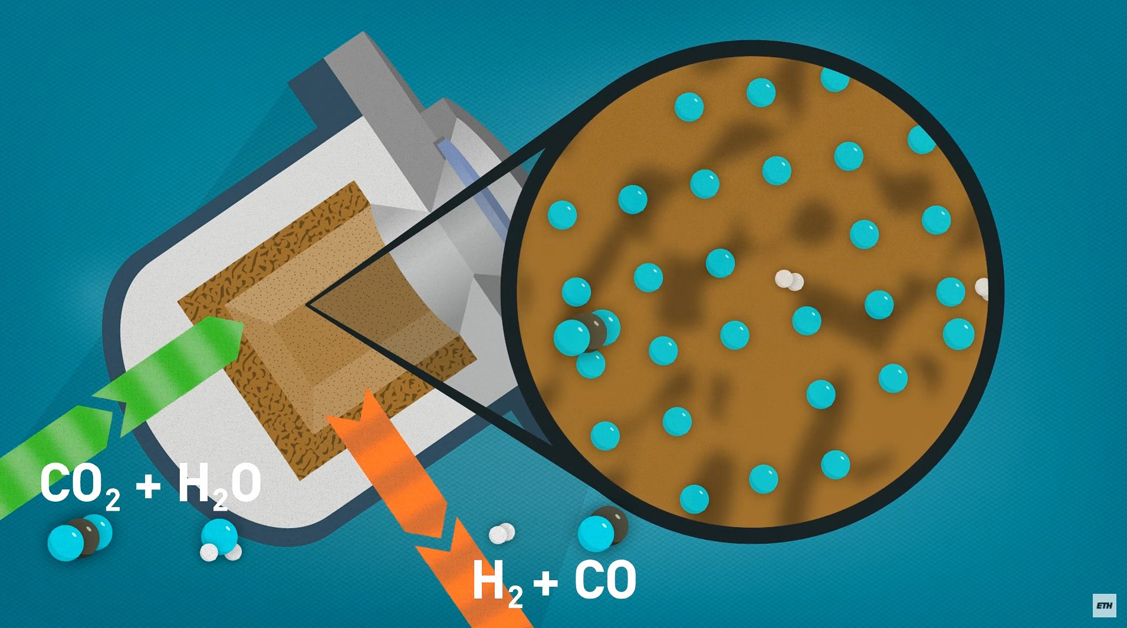

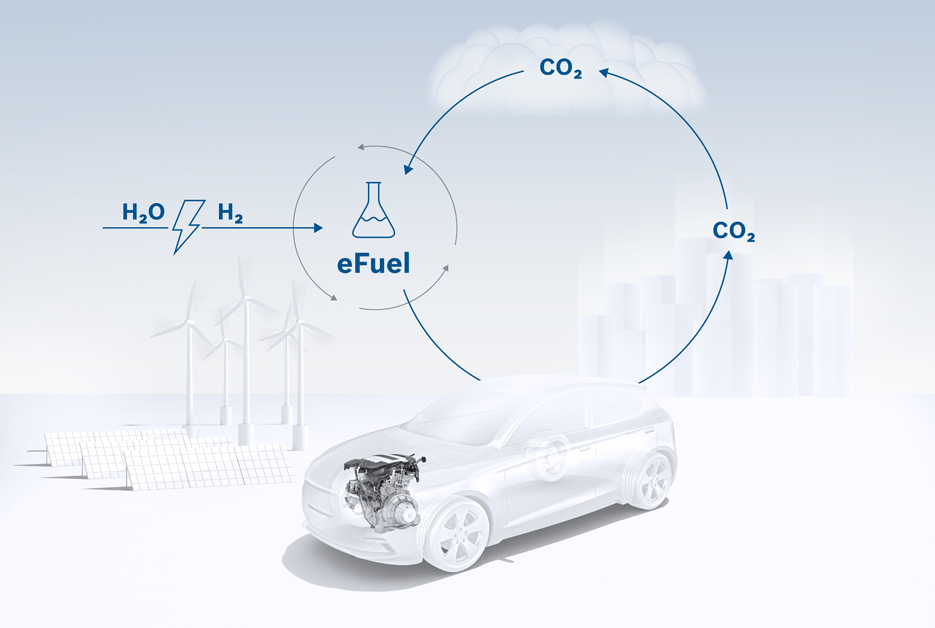

Used as a general term for ‘synthesised hydrocarbon liquid fuel’, e-fuel can be made by combining carbon dioxide and hydrogen – extracted from air and water respectively – into a combustible mixture called syngas.

Formula 1 has a 2030 target to be 100 percent net zero

From this, using a series of chemical reactions known as the Fischer-Tropsch process, it’s possible to create liquid hydrocarbon fuels that can be formulated as drop-in replacements for petrol, diesel, aviation fuel; essentially anything that’s traditionally made by distilling crude oil. Provided the hydrogen and carbon dioxide are extracted using renewable, green energy the resulting e-fuel is carbon neutral.

Like normal petrol, it releases carbon dioxide into the atmosphere, but the same amount of CO2 is removed from the air during its manufacturing process. These e-fuels aren’t to be confused with biofuel, as they’re not derived from plants but are completely synthetic.

Porsche is pushing the e-fuels agenda, but will the infographic become reality?

It’s not an entirely ‘zero emission’ fuel as there will still be traces of nitrogen oxides in the exhaust, but in terms of greenhouse gases an ideal e-fuel process would have no net contribution to the problem.

The EU has long had a target that by 2035 all new cars sold should be zero-emissions vehicles in terms of greenhouse gases. Initially, e-fuel was dismissed as there are still exhaust emissions, but earlier this year the target was revised to allow e-fuel combustion engine vehicles provided the e-fuel is truly carbon neutral.

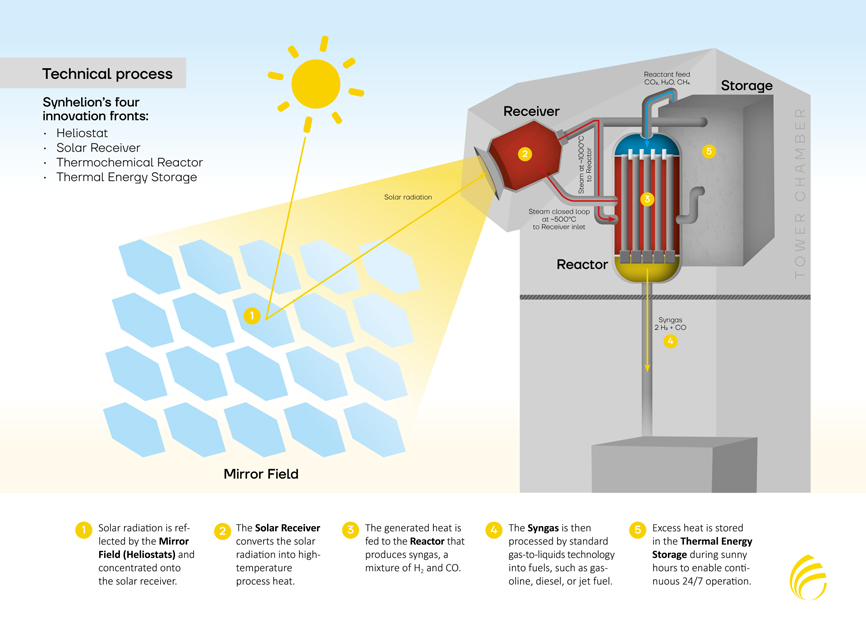

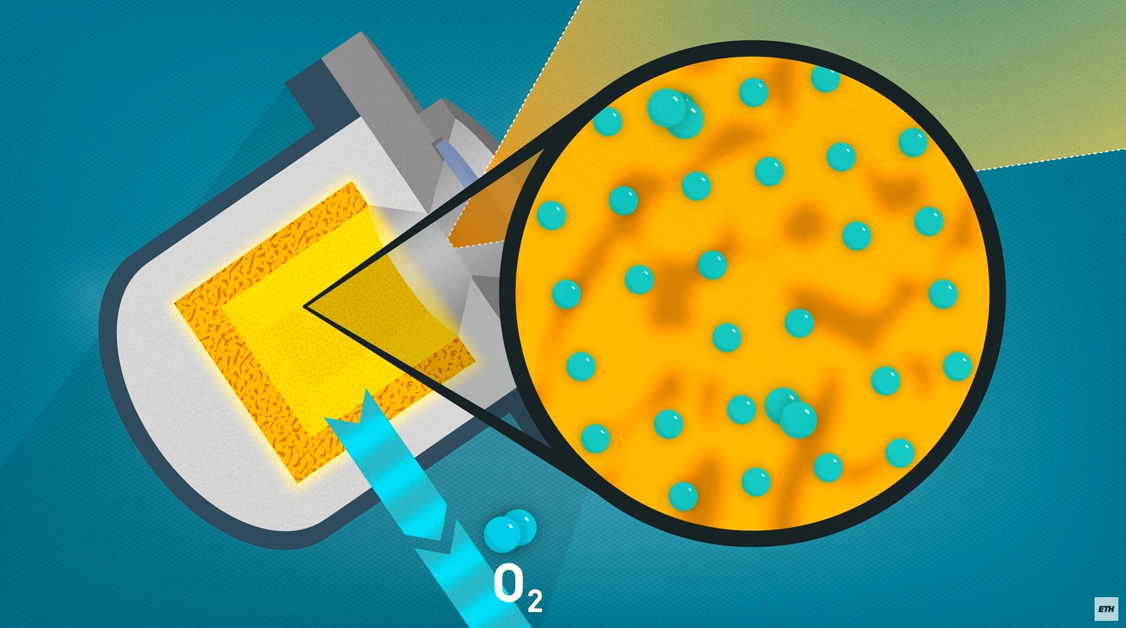

Synhelion’s e-fuel solar process

The mechanics

Several car makers, including Porsche, Audi (both linked to Ducati via the VW group) and BMW have already made investments in e-fuel projects, but the biggest driving force behind the technology is aviation. Aeroplanes, particularly large, long-range airliners, have no realistic prospect of being able to switch to battery power in the foreseeable future, and another alternative – hydrogen – is also fraught with problems.

For aircraft, e-fuel could prove to be the silver bullet. Motorcycles, while earthbound, face many of the same problems as aeroplanes in terms of switching to electric or hydrogen power. Like planes, their performance, range and useability are directly connected to the energy-density of the fuel they carry and, unlike cars, they have no leeway to add more size or weight to the mix without paying a huge penalty and becoming distinctly inferior to the current state-of-the-art.

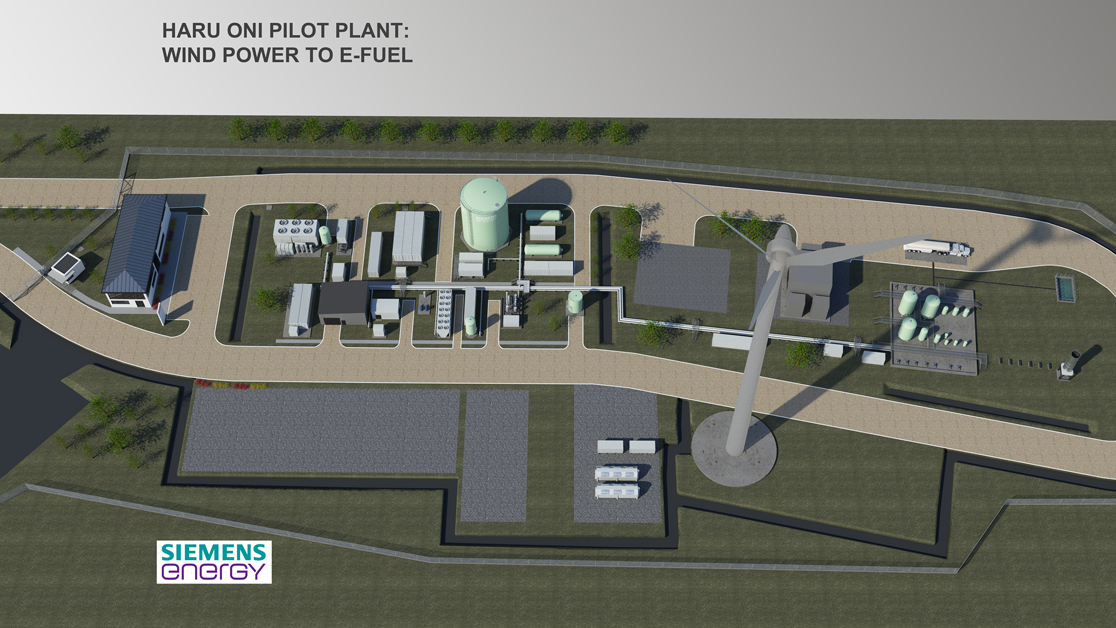

A pilot plant to convert wind power to e-fuel

Jamie Turner is a Professor of Mechanical Engineering at King Abdullah University of Science and Technology in Saudi Arabia and has an illustrious background in combustion engine design. He worked for Norton back in the firm’s championship-winning Wankel rotary days, going on to head the powertrain research at Lotus and later Jaguar Land Rover.

“Fuels that we use are fossil fuels and we are releasing CO2 into the atmosphere,” he begins. “The solution that everyone seems to think is the only thing that’s going to work is to completely change the energy distribution system to electricity, for which we have no infrastructure as far as transport is concerned.

The e-fuel production process

“You have to develop new mining processes, new mines for lithium, for cobalt, all the other stuff – which is all in really short supply. You’re trying to change everything at once without looking at the real problem, which is CO2 in the atmosphere. If you take the e-fuels route you’re addressing that problem without trying to change everything else simultaneously. We have to do it anyway for aviation, so why not try to grow it to cover everything?

“The bit that everyone thinks of as being really sci-fi is ‘where do you get the CO2 from?’ and the logical extension is that the cleanest way of doing it is to extract it from the atmosphere. There’s plenty up there, as we know. Those processes have actually been well understood for many years. It’s how you keep people alive on nuclear submarines: they have to extract the CO2 from the atmosphere. So that’s all well understood, chemically. There’s a Swiss company called Climeworks that does it commercially already.

Converting from gas to liquid

“So you’ve got CO2, extracted from the air, and hydrogen from electrolysing water, all using renewable energy. Put those together and you can synthesise hydrocarbons. There are some quite neat things about this. You can site these plants anywhere in the world where there’s a lot of renewable energy, like hot deserts.

“Normally, trying to get the energy out of a desert is difficult. You can’t do it as electricity because they’re usually too far away from where you want to consume the energy. Think about the Sahara or Australia – any of the really hot deserts around the world – and instead of trying to get the energy out as electricity, you can synthesise a hydrocarbon and transport that.

“Most of the world’s really poor nations are really poor because they’ve got a superabundance of what we want in the West, and that is energy in the form of solar. Nothing grows there, but it’s still energy. So you could help lift countries out of poverty because, once you’ve built the plant, on an operating level they’re free. Sunshine is free.

“Air is free. Water might be slightly problematic, but nevertheless, if you have a coastline then water is basically free. What you make is something with a very high value-added aspect in the form of liquid fuel.”

It’s not just science fiction, either. There are already real plants turning out e-fuel using exactly this process. Siemens and Porsche have built the Haru Oni pilot plant in Chile and, while its production is limited at the moment, it’s planned to be able to turn out 550 million litres of e-fuel annually by the end of this decade.

The Haru Oni desert plant in Chile

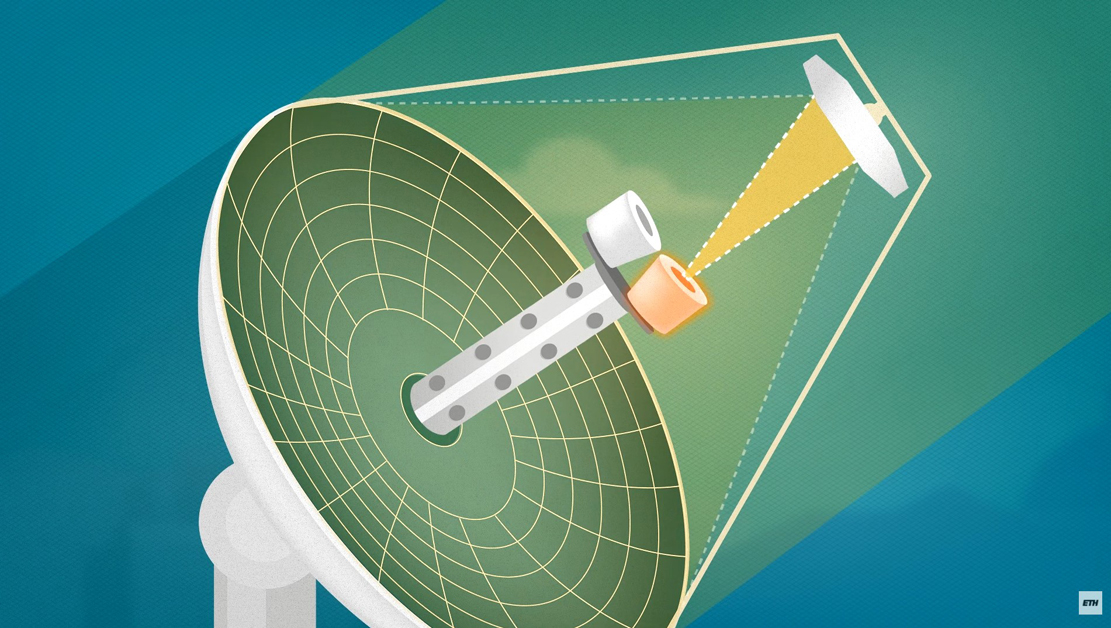

Other active projects also include a prototype for a direct air-to-fuel system, made by ETH Zurich University in Switzerland, that takes both water and CO2 from the air and, using sunlight to heat and activate catalysts, converts them into oxygen and liquid hydrocarbon fuel. It only makes tiny amounts of fuel at the moment but has the potential to be scaled up.

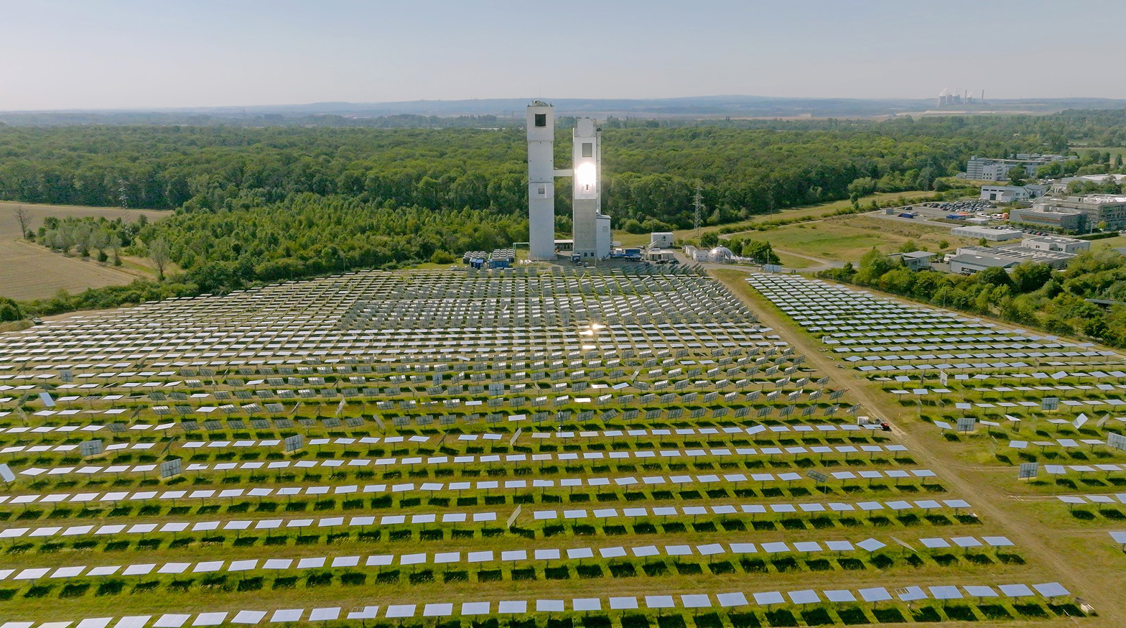

Another company, Synhelion, is scheduled to open the world’s first industrial solar fuel plant, with plans to ramp up production to 875 million litres of aviation fuel per year within a decade. The same tech can also make gasoline or diesel as drop-in replacements for road vehicle fuel.

Mobil is MotoGP’s e-fuel supplier

What’s the catch?

There are some downsides to e-fuel, and the one critics will highlight is its inefficiency. It takes a lot of energy to make.

Combustion engines are already relatively inefficient in turning the energy in petrol into motion. A lot is wasted in heat and noise, so most are between 20-30 percent efficient, although the high-tech V6 hybrids currently used in F1 racing, the pinnacle of combustion engine design, are hovering around 50 percent efficiency. With e-fuels, this problem is compounded by the fact that electricity is used to make it. With current technologies, somewhere between 5-10 percent of the energy used to create the e-fuel ends up at the wheel of the vehicle burning it.

Haru Oni’s production goal: more than 550 million litres of e-fuel per year by 2026

That sounds pretty bad, but the flexibility that e-fuel offers offsets the problem. Like existing liquid fossil fuels, it’s easy to transport and easy to store – something that can’t be said for alternatives including electricity or hydrogen (and a hydrogen-based economy has a similar problem in terms of needing a lot of electricity to electrolyse water and extract hydrogen). That means it’s possible to site the plants creating the fuel in inhospitable environments like deserts where there’s abundant solar energy.

Turner continued: “I’ve calculated several times, always with the same answer, that if you cover one percent of the Sahara with solar panels – at current efficiencies – and go through all of the efficiency chains to make a hydrocarbon, then you can gather, convert and make storable energy at the same rate that we use it for the whole European transport fleet.

Synhelion’s massive solar mirrors

“If you look at the amount of solar energy that hits the world on a daily basis, we have over 1800 times as much energy hitting the world as we use for everything. My view is that people who think this is about energy don’t understand the problem. It’s also about the ease with which you can employ the solution and whether you can do it gradually.

“With electrification, you have to change everything. With e-fuels we could theoretically make fuels to exactly the same standards as we use at the moment, and actually make them better within those standards because we’ve got a chemical process instead of just digging stuff out of the ground, lightly polishing it and shoving it into fuel tanks. We can control the process.”

Another downside is cost. While e-fuels will get cheaper as production increases, they’re likely to be substantially more expensive than petrol or electricity for the foreseeable future.

A fair-sized paddock, too!

Blend and stretch

E-fuel doesn’t have to be an all-or-nothing switchover. They are blendable, meaning they can be mixed with fossil fuels to gradually decarbonise as production ramps up.

“You can start to decarbonise all the vehicles as soon as you put e-fuel into the distribution system,” adds Turner.

Super Soco’s TC Max e-commuter

Motorsport is already heading in the direction of e-fuel, recognising that carbon-neutrality is vital. Formula 1 has a 2030 target to be 100 percent net zero, and from 2026 the racing cars themselves are due to use a ‘drop-in’ sustainable e-fuel instead of fossil fuel. MotoGP has set itself a deadline of 2027 to do the same thing but will first adopt a 40 percent e-fuel mix for next year.

Simply filling tanks with an e-fuel engineered to replicate the characteristics of their original fossil fuel immediately turns vehicles into net zero contributors to global warming. So since the manufacturing of new vehicles accounts for a substantial part of their lifetime emissions, anything that extends the life of an existing one should arguably be championed.

What about hydrogen?

Hydrogen has recently become a focus of the ‘big four’ motorcycle companies with Honda, Yamaha, Kawasaki and Suzuki joining forces in the new ‘HySE’ research body, created to develop small-capacity hydrogen-fuelled combustion engines with a particular focus on motorcycles.

Since the main emission from burning hydrogen is simply water (although, as with e-fuel, there will inevitably be some trace emissions of other gases like NOx), hydrogen combustion engines are a tempting proposition. However, there are still substantial hurdles.

Hydrogen: is it just too cumbersome to become a mainstream energy solution?

Like e-fuels, which also require hydrogen in their manufacture, there’s a substantial electrical energy requirement to create hydrogen from water, and that electricity needs to be generated renewably for the hydrogen to be considered ‘green’ and give the desired net-zero impact.

However, hydrogen is much more difficult to transport and store than liquid e-fuel. Its small molecules mean pipelines and tanks are likely to suffer leaks and its thin density means it takes up a large amount of space unless it’s compressed to extremely high pressures or chilled to -253°C to become liquid. The high pressure and/or low temperature means refuelling isn’t a simple task, and there’s currently no infrastructure to support a network of filling stations.

The e-fuel equation: looks so simple, hey?

While hydrogen is nearly three times as energy-dense as petrol, that’s based on weight rather than volume. Even in liquid form hydrogen is a fraction of the density of petrol, so to get the same range from a hydrogen-fuelled combustion-engine bike as from a petrol one, you’d need a tank around three times as big. Combustion engines also need to be substantially redesigned for hydrogen. Forced-induction and direct fuel injection are vital to get close to the same horsepower-per-litre outputs as a normal petrol engine, so there’s no prospect of existing bikes being able to be reworked to switch to hydrogen fuel.

“Hydrogen combustion engines won’t be as efficient as fuel cells, but they have serious advantages in other respects,” Turner said. “One is that they’re dirt cheap to make. Engines are really cheap in comparison to any of the other technologies – batteries or fuel cells.

LiveWire, Harley-Davidson’s electric subsidiary

“The other advantage is that a hydrogen combustion engine can happily consume hydrogen with quite a lot of trace molecules, like carbon monoxide, that will poison a fuel cell in minutes. So having hydrogen engines to pull the hydrogen infrastructure forwards as you make the hydrogen cleaner is quite a neat flexibility.

“The problems with hydrogen are storage and safety. It’s actually got some nice characteristics for combustion engines, but you can’t easily convert a vehicle to hydrogen operation.”

The reality is that if we’re going to make a success of transitioning from fossil fuels to net-zero solutions, the future is likely to see electric vehicles, e-fuels and hydrogen power being adopted, each playing to their own strengths in the parts of the market that suit them.

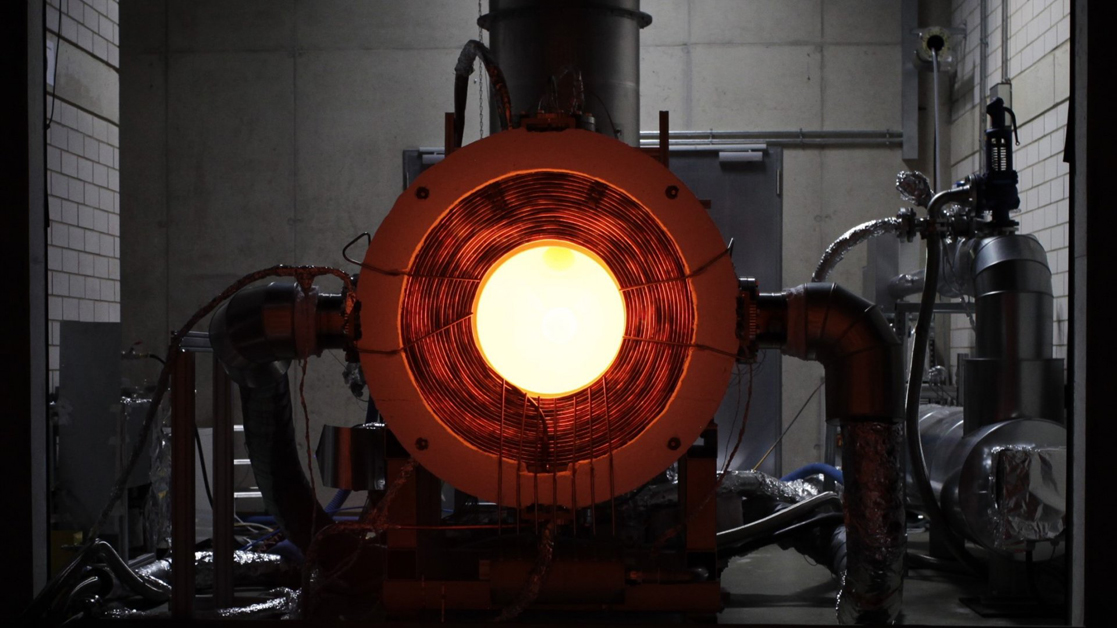

In test mode at Synhelion

Words Ben Purvis