Cornering ABS seemed impossible until recent tech breakthroughs brought it into the mainstream

Five years ago ABS brakes were still a straightforward technology in the most literal sense: they only worked when you were going straight forward. Now that generation of anti-lock is fast heading for the history books as cornering ABS becomes increasingly widespread.

Game-changing technology doesn’t come along often in motorcycling, but despite a quiet start – it first reached showrooms on the 2015 KTM 1290 Super Adventure – cornering ABS is now becoming the sort of kit that we notice when it’s not fitted rather than when it is.

How does it work?

Motorcycle ABS first reached production in 1988 on the BMW K 100, 10 years after the same Bosch-developed technology had appeared on cars. But it lacked the key benefit that car-based anti-lock offered; the ability to steer around obstacles while the ABS was operating. That’s because bikes lean in corners, and it’s a problem that took decades to solve.

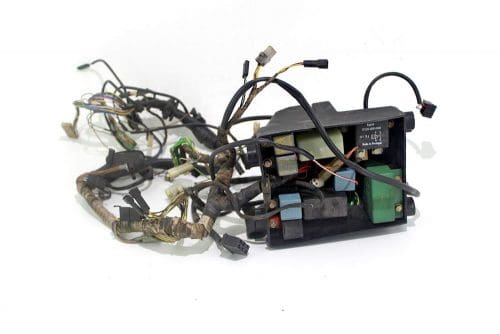

Old-school motorcycle ABS only featured one set of sensors, measuring the speeds of the front and rear wheels. The system’s simple computer could then compare the two wheel speeds. If one turned significantly slower than the other under braking, it was an indication that wheel was skidding so the ABS system would momentarily release brake pressure on that wheel.

The problem is that when you’re banked over in a corner, a bike’s front and rear wheel speeds change in relation to one another. Different wheel diameters, tyre widths and tyre profiles throw in a host of variables that mean a simple comparison of front and rear wheel speeds becomes useless.

What’s the solution?

The solution came in the form of the Inertial Management Unit, or IMU, that provides a vast amount of additional information to the ABS computer. IMUs, first developed by Bosch in 2007, were initially intended for traction control systems, but the same information that helped bikes go faster without crashing is also vital in helping them slow down.

The essential technology in an IMU is MEMS – Micro Electro-Mechanical Systems. These are sensors on a chip; accelerometers and gyroscopes. The former measures acceleration in three axis – side to side, forwards and backwards, and up and down – while the latter measures pitch, roll and yaw.

Suddenly there’s a vast ocean of information available – lean angles, roll rates, deceleration, sideways slip, front and rear brake pressure and more – that allows the bike’s computer to constantly calculate how much grip is available at each end.

What’s the difference?

It means that rather than waiting for a wheel to lock before releasing the brakes, as on old-fashioned ABS systems, the bike can intervene before you run out of grip to make sure you’re right on the limit of braking while still able to maintain an angle of lean. In short, you can brake and steer at the same time.

It’s not straightforward anymore, but the good news is that the sensors-on-a-chip that make this possible are increasingly affordable and the remainder of the ABS system is effectively the same as before – and that means it won’t be long before cornering ABS is the norm, rather than the exception.

Then

Now

Words Ben Purvis Photography AMCN archives