How BMW just made carbon fibre a whole lot cheaper

While the Ducati 1299 Superleggera or BMW HP4 Race means you can buy a carbon-framed motorcycle right now, the technology is still a long way from being mainstream and affordable to most, but BMW is changing that.

The German company has developed a system to mass-produce carbon parts using injection moulding, allowing automated machines to turn out complicated component in under a minute.

The technology has proven good enough to win an international innovation award from carbon fibre specialist organisation JEC Group. The demonstration of the new tech used a motorcycle swingarm as its subject, a good sign it is intended for motorcycle applications.

While there’s no word on the carbon swingarm’s future, the component looks like it has been designed to fit the BMW G310 range of bikes.

Project manager Elmar Jäger said: “We opted for chassis components which are under continuous load since the requirements involved are especially demanding.”

Fellow team member Joachim Starke added: “In addition to achieving weight benefits and cutting costs significantly, we also managed to develop a technology that allows precise configuration of component properties by using a variety of composite and metal inserts.”

There’s already plenty of speculation that the carbon frame of the limited-production, track-only, HP4 Race will be reworked into a more mass-made design for the next generation of S1000RR, so it’s possible a carbon frame and swingarm will be offered on higher-spec, but still road-legal, derivatives of BMW’s flagship superbike.

…But it’s not as we know it

If you’re hoping for the eye-catching look of the usual complex carbon-fibre weave style, you’ll be disappointed.

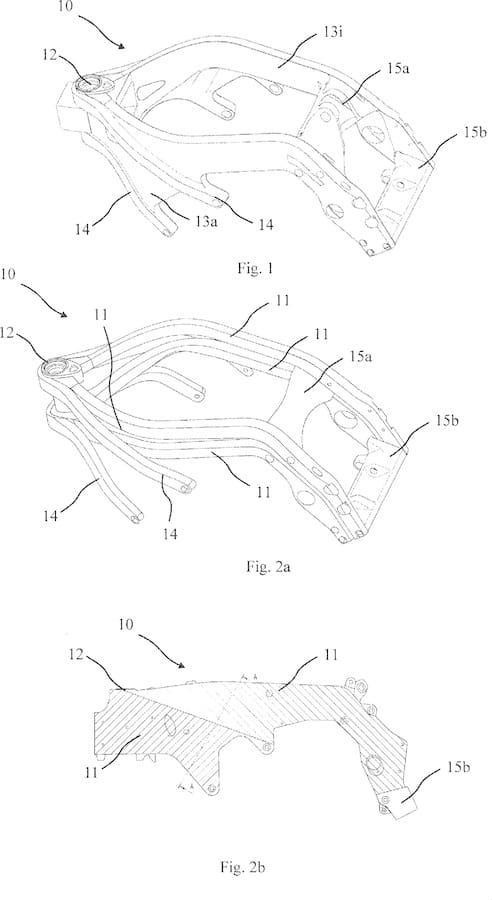

The new tech uses short carbon strands mixed with plastic, allowing a molten mixture to be injection-moulded. Longer, directional fibres are used in key stress points and a carbon-fibre tape is added in places for extra reinforcement.

“An injection mould part with short CFP recycling fibres is used where the stress levels are not as high,” Jäger explained. “CFP in the form of high-strength endless fibres is used where required by the stress pattern. In this way, we developed a cost-efficient design that can be scaled.”

Carbon dated

The new technology fits in neatly with a set of patents that BMW published in 2015.

While one of these patents effectively previewed the carbon-framed HP4 Race, showing how BMW planned to mass-produce an S1000RR-style beam frame from the material, the second patent was more concerned with low-cost machines.

It proposed a system using endless carbon-fibre woven tubes that could be pultruded and cut to length before being joined into a trellis-style chassis – the sort of chassis used by BMW’s G-series singles and R-series Boxers.

By Ben Purvis