EV range anxiety remains a major roadblock to widespread uptake. Now a smart new aero design could help riders go farther on a charge

Aerodynamics is a hot topic these days. Especially in MotoGP, where winglets, airducts and other such devices improve lap times and prolong grip via increased tyre life. But this enhanced aerodynamic efficiency has yet to be translated to customer road bikes, other than a small selection of expensive, low-volume, ultra-high-performance racers-with-lights that are targeted at Superbike race grids. That’s likely to change in future generations of electric two-wheelers, thanks to the intelligent application of aerodynamic technology developed by a company in the hinterland of the F1 racecar industry in the UK.

There are three essential factors governing the science of forward motion: torque, weight and aerodynamic drag. Torque (not power, which is of secondary importance in getting the show on the road via acceleration and keeping it there) is the means by which the mechanical source, be it a pair of human legs, an engine or a full electric motor, transmits the necessary force to the wheels to deliver that motion. Weight relates to the object that has to be driven forward, and the heavier it is, the harder it is to achieve, especially starting from a dead stop. And aerodynamic drag is the force that combats forward motion via air resistance. Such drag increases with speed – the faster you go, the greater the drag – and is caused by friction between the air and the vehicle’s surface, and by differential air pressures around the vehicle. Combating this drag dissipates energy from fuel, making vehicles less efficient and increasing fuel consumption. But if the vehicle partly consists of fresh air, of nothingness, with a gap where there’s usually a mass of metal or plastic or whatever, then of course that section has zero drag, meaning none of the above demerits apply.

FAST TRACK TO EFFICIENCY

Robert White, 44, is an ex-F1 development and race technician, having worked in the McLaren team’s R&D squad at the outset of the current Hybrid V6 era, when he first became involved with electric powertrains. He acted as Jenson Button’s engine technician in the former world champion’s final season in Grand Prix racing and, like so many others working in F1 and satellite motorsport companies, is a hardened biker. He’s also very much a man who thinks outside the envelope of convention. As such, White has come up with a unique way to produce a more energy-efficient Powered Two-Wheeler (PTW) than almost anything else on the planet. For four years ago he unveiled the remarkable electric motorcycle on which he’s seeking to break the 456km/h (283mph) outright land speed record for the fastest E-PTW under 300kg, set by former WorldSBK champion Max Biaggi in 2021 on a French Voxan streamliner.

The White Motorcycle Concepts/WMC E-LSR bike, codenamed Project WMC250EV, has a unique aerodynamic structure aimed at dramatically reducing drag via a large central duct running along the entire wheelbase, which allows air to flow straight through the centre of the motorcycle to deliver outstanding aerodynamic efficiency, while retaining a relatively conventional riding position. It’s like pushing on an already open door – there is zero impediment to the airflow, therefore nil aerodynamic drag.

When you see it for the first time it’s hard to avoid laughing out loud, as I will admit I did back in 2021 – not in scorn for the design but, because it’s so obvious, you can’t imagine why no-one thought of this before. But nobody did, so full credit to Rob for inventing the obvious! Let’s hear him tell us how, and why.

“Aerodynamic drag is your chief adversary in designing any vehicle whose aim is to go faster than anything else in a straight line, together with high speed aerodynamic stability,” says White. “So the WMC250EV is the most radical application of a new aerodynamic concept invented by White Motorcycle Concepts. It removes the centre of pressure from the front of the bike to counter front-end lift via our patented design of a venturi which runs front-to-back between the rider’s legs. This also significantly reduces the drag, which in turn enhances acceleration and reduces fuel consumption. But we’re only able to package such a design thanks to the new opportunities created by jettisoning an ICE powertrain in favour of smaller, more compact electric motors, which are fuelled by cylindrical cells that can be more evenly and more ideally distributed around the bike.

“Having worked in Formula 1 and spent many, many hours staring at an F1 car, I know that it’s all about packaging. And generally the engineers’ targets are to package as tightly as can be, to give the aerodynamicist as compact a vehicle as possible, so they can exploit the volumes available for aerodynamic gain – which is exactly what we’re trying to do here.”

White’s application of this technology to the Project WMC250EV package helped achieve a claimed 70 per cent reduction in drag compared to the baseline of the self-tuned Suzuki Hayabusa with which White had become a very successful drag racer and sprinter pre-2020.

POWER PARTNERS

In order to generate revenue to underwrite the costs of the E-LSR project, White Motorcycle Concepts is seeking commercial applications for its patented airduct technology.

“The WMC250EV has a fantastic drag co-efficient of 0.118, so it’s arguably the lowest drag motorbike in the world with a standard seat height,” says White. “That was very satisfying, but then we needed to bookend it to see what is the lowest speed range at which a motorcycle would benefit from such technology. Generally speaking, drag increases with speed, so on a motorcycle travelling at 40mph, a massive 50 per cent of the energy coming out of the powertrain is already being spent to overcome aerodynamic drag. By the time you get to 70mph, it’s around 90 per cent of that energy – there are very few frictional losses within the powertrain, such as between tyres and road surface, or wheel bearings, or chain or belt final drive etc. Our technology is powertrain agnostic, so as long as you can free up the space within the motorbike to mount the ducts, then the concept is relevant to any bike, be it hydrogen, electric, or combustion, or whatever.”

However, adapting this technology to road-legal two-wheelers might be a struggle when the bike in question uses an ICE powerplant – but EVs are another matter and in the world’s leading electric motorcycle (as opposed to scooter) manufacturer, Zero Motorcycles in Northern California, White has found a willing partner.

“I first met Rob at the 2023 EICMA Milan Show,” says Zero’s VP of Product Development, Brian Wismann. “I was familiar with the White Motorcycle Concepts project land speed bike, and was very interested in that. After meeting up, we both had a simultaneous epiphany that the unique packaging of the batteries on our SR/S and SR/F streetbikes lent itself really well to their technology of putting a hole through the middle of the bike to reduce frontal area, and drag, which in turn allows you to travel that much farther on the same charge. Of course, we’re always looking for ways to increase range on the bikes, and here’s an opportunity to do so without increasing charging time or weight. You almost never get efficiency for free, but here was an opportunity perhaps to do just that!”

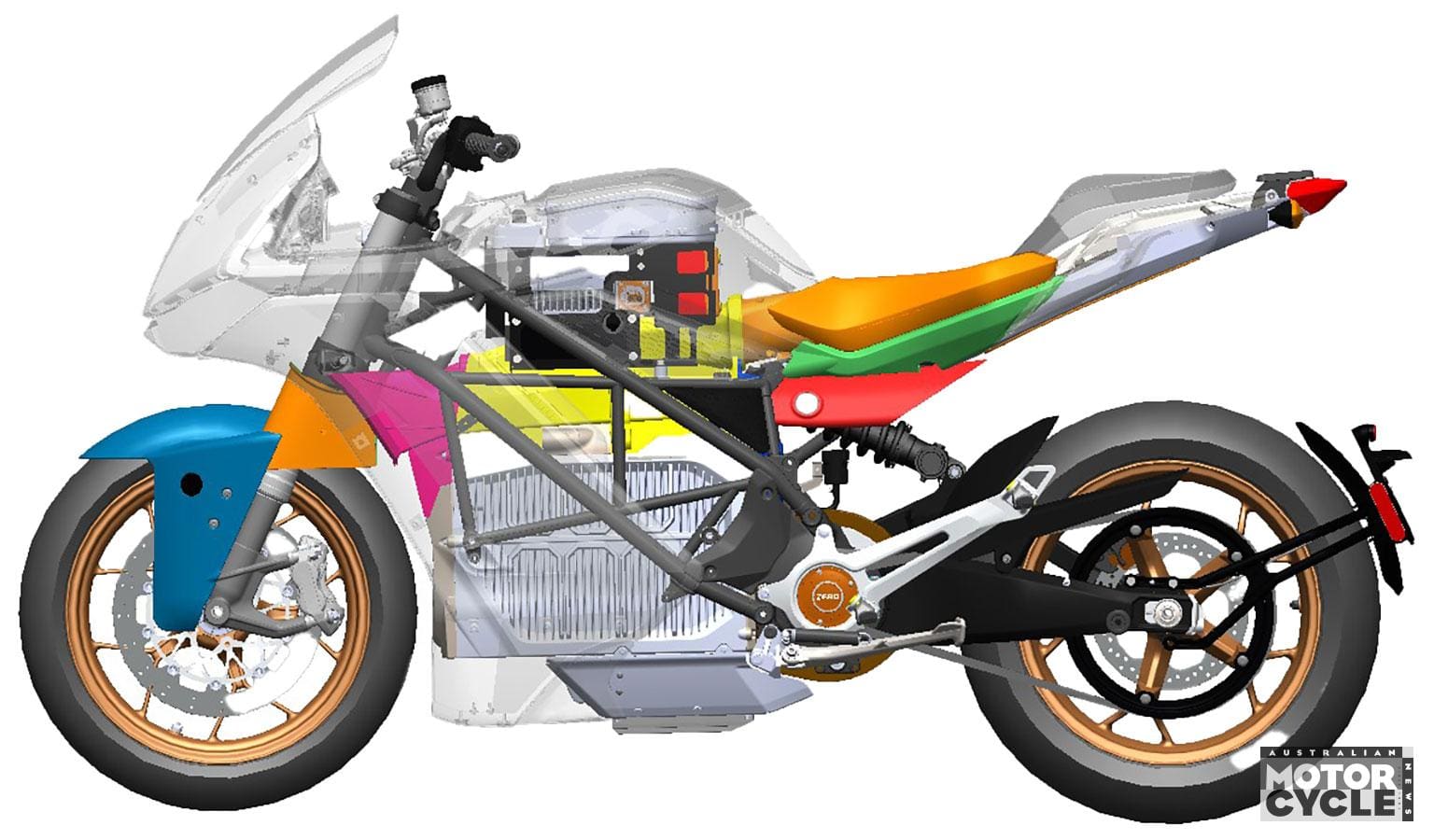

Zero joined forces with WMC on a joint venture to engineer its concept into a stock SR/S model, to explore how the system might benefit future Zero production bikes. However, this meant that on the WMC Zero SR/S prototype, White had to work within the confines of the existing chassis, without altering its structure or the main powertrain components – including the stock battery pack and Zero’s own ZF75-10 passively air-cooled brushless AC motor. This is a radial flux sealed design delivering 82kW (110bhp) at 5000 rpm, and a constant Nm190 of torque, where the interior permanent magnets are located on the single moving part (i.e., the rotor), while the components which get hottest, the windings, aka coils, are mounted on its periphery, dissipating the heat via a deeply finned circular aluminium housing, without the weight or complexity of liquid cooling.

This meant that installing such a large duct as on the WMC E-LSR motorcycle, which a 10-year-old child could crawl through, was impossible to achieve. Instead, the re-engineered Zero SR/S concept incorporates a bifurcated aerodynamic duct running directly through the centre of the bike, channelling air from behind the front wheel to exit above the rear wheel via twin ducts in the underside of the seat. To enhance the airflow through those ducts, WMC has also created a new aerodynamic front mudguard and a pair of teardrop-shaped fork shrouds that together ensure the entry of the maximum feasible airflow into the passageways.

FEEL THE FLOW

The air enters through a single intake duct positioned above the front wheel and below the standard bodywork’s nose. It then splits into two separate channels running over and above the steel-framed battery box, which essentially comprises the chassis of the motorcycle. These channels direct that airflow around immovable horizontal sections of the chassis before venting it through a pair of under-seat extraction outlets.

Although it’s not as evident as on the E-LSR bike, if you crouch down at the front or rear of the WMC Zero there’s still a direct line-of-sight through the ducting to the other end, showing how unobstructed the airflow’s path is. And the overall aesthetic is still very pleasing – the clean, shapely but still wind-cheating lines of the stock SR/S, created by Zero’s Director of Industrial Design Matt Bentley and his three-man team, are visually unaffected by the WMC ducting. The main architectural difference compared to the stock SR/S is that the seat has been raised 40mm via a special subframe, to provide extra space for the twin airducts.

“The major elements of the bike are all in their original position, and we did not relocate or alter the composition of any of the batteries,” says White. “The energy storage is in the same position, so is the motor, and the frame and the motor controllers are in the same place, too. The onboard charger and a number of electrical boxes, including the VCU/vehicle control unit, the BMU/battery management unit and the supplementary 12-volt battery system’s fuse box were all relocated into a steel structure which basically replaced the existing module which was mounted to the chassis, and we remade that and repositioned all those parts within the bike. We’ve also moved the charging plug socket from its position behind the tank and repositioned it inside the empty space above the so-called ‘tank’. That’s all.”

MAKING STRIDES

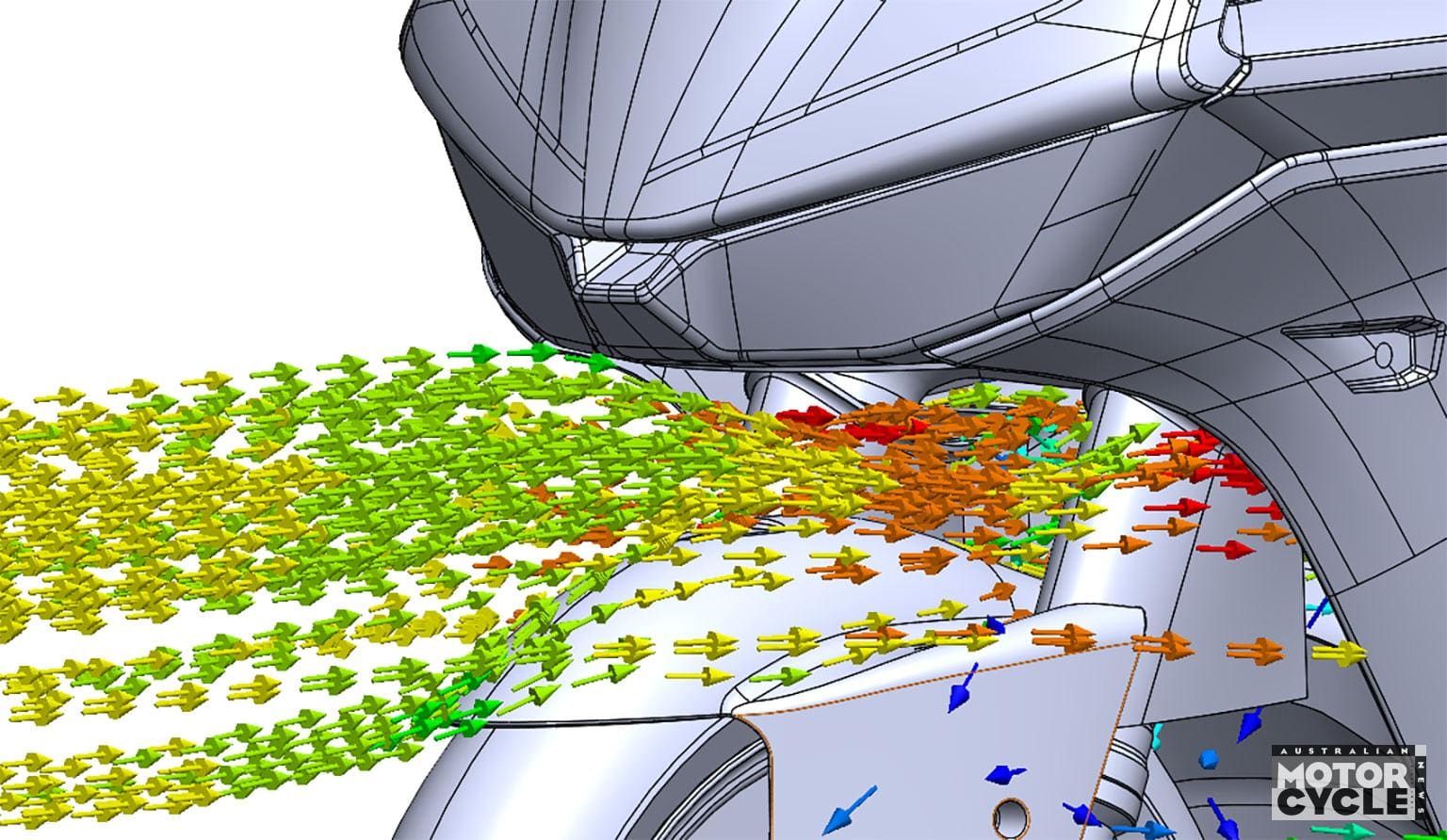

This proof-of-concept prototype is the product of the accelerated development program the two companies have been working on since February 2024, when the stock Zero SR/S and its related CAD data were delivered to WMC’s Northamptonshire base, around 48km from the epicentre of Britain’s F1 industry at Silverstone. A base CFD/Computational Fluid Dynamics model of the stock bike was built to try and replicate digitally its aerodynamic features, including the drag and flow path through the standard motorcycle. Having created that model following processes White had become proficient in during his years working in F1, the WMC engineering team developed the concept, using a range of in-house modelling and CFD simulation techniques, plus prototyping and validation. They also employed self-built aero rakes of the type commonly used in top-level motorsport. This enabled both computer simulation and, finally, real world testing, which began last October with White running up and down the nearby A14 freeway to establish and/or confirm some baseline data. The bike was completed early last November, and duly made its global debut on the Zero stand at the UK’s largest motorcycle show, Motorcycle Live in Birmingham, on November 16.

According to White, these tests confirmed that the evolved twin-channel design has delivered an 11.2 per cent increase in aerodynamic efficiency versus the stock SR/S. That’s despite the limitations imposed by working within the confines of a standard production bike, retaining the same external bodywork. This has duly resulted in a 10 per cent boost in the machine’s range per charge at highway speeds – and range anxiety is of course a crucial aspect of EV ownership, as well as a notable deterrent in widespread adoption of the tech. But White believes there’s another 7 per cent of extra gain there for the taking by working on the external surfaces of the existing bike, at the cost of essentially restyling it. He says: “The whole EV industry is currently facing a huge technical/commercial challenge to produce an electric motorcycle with performance close to its petrol equivalent, coupled with convenience in everyday use. This problem will not be solved by battery technology alone. It requires a blend of innovations to bridge the gap now and provide efficiency benefits in the future. When I first saw the Zero SR/S frame and battery architecture, I immediately recognised the opportunity to retrofit a duct. That’s because they have a massive kind of suitcase-type energy storage which sits relatively low in the chassis, and they’ve committed to AC onboard charging, so they have a charger that sits on the top. I’m proud of what we’ve achieved, even if the duct is limited by existing packaging constraints.

“Our intelligent aero duct has been proven to enhance aerodynamic efficiency, positively impacting upon power consumption and range, especially at high speeds. But it would offer even greater benefits if it could be integrated from the very start of the design process.”

That enhanced aerodynamic efficiency gain can be used to extend range and/or lower costs, reducing the need for a larger battery, which in turn cuts down on weight, charge time and battery costs. “From our initial meeting at EICMA 2023, we’ve been interested in understanding the potential impact of WMC’s aerodynamic duct,” says Abe Askenazi, CTO of Zero Motorcycles. “As a company we’re committed to innovation and, while battery development is advancing rapidly, we believe a combination of technologies is the key to developing the electric motorcycles of the future. This proof-of-concept WMC bike has given us valuable insights into the potential benefits of integrating an aerodynamic duct into electric motorcycles. If you’re riding on a freeway on a longer journey, it gives 10 per cent more range via reduced mass, which is pretty great. And WMC have not detracted from the battery load at all – they were able to install those two ducts essentially without modifying the chassis or the powertrain, and with the exact same battery configuration, which is pretty fantastic. I also love the look of it, too – I think it’s fantastic!”

TIME TO RIDE

The chance to become the first person outside WMC to ride the bike – and ahead of anyone at Zero Motorcycles! – came via a brief 90-minute ride on slippery, salt-coated country roads on a sunny but chilly English winter’s day. Having ridden each iteration of Zero’s product development since 2012, and already being familiar with the SR/S via riding it from the Zero factory in Northern California, I wasn’t as interested in exploring its performance – just as well, given the road conditions! – as I was in comparing how the 40mm taller seat height affected the riding experience.

The answer is: hardly at all, especially since the stock 787mm SR/S seat height is already pretty low by the standards of today’s sportbikes, particularly with the relatively high one-piece taper-section handlebar and Zero’s very individual positioning of the pretty large rearview mirrors under the handlebar grips rather than above them. Raising the seat height to 827mm actually delivers a more spacious and in my case – at 180cm in height – a more rational stance, yet without any sense of reaching down to grasp the handlebar that’s directly mounted via a 50mm riser to the upper triple clamp, which might have put undue weight on my shoulders or arms. True, there’s a slightly smaller cubbyhole space atop the ‘tank’ in which the charging cable now lives, but the exterior shape of the ‘tank’ is unaltered.

Thanks to the spacious seat design that’s usefully narrowed where it meets the tank, despite its taller height I could not only put both feet flat on the ground at rest, but also move around easily on the go. You’re not wedged in place at all, plus the TMC SR/S seemed really well balanced, despite its relatively high 229kg weight.

The one-piece aluminium handlebar delivers a slightly leaning-forward riding stance, which is totally comfortable and not at all tiring. This bike feels extremely taut and very together when you ride it. And even in the slippery conditions (which the bike’s TC handled with ease), I found the performance of the Zero to be genuinely intoxicating. It’s that literally seamless yet controlled delivery of the massive torque available as soon as you open the throttle that’s so invigorating.

Despite the icy conditions, riding the Zero SR/S was just as much fun as the last time I did so in NorCal, thanks to the way the Cypher III ECU harnesses the huge 190Nm dose of constant torque via four pre-programmed riding modes (Street, Sport, Eco, Rain) and up to 10 programmable Custom modes monitored by the TFT dash interface. Flicking easily between Rain mode, for traversing the slippery tighter turns, and Street, for the faster curves and straighter stretches of the East Midlands roads, meant enjoying the protection of the Bosch MSC/Motorcycle Stability Control system incorporating Cornering ABS, traction control and drag torque control. But sorry – I didn’t cover enough distance to do a ‘fuel’ consumption test!

While it’s unclear at this stage whether Zero will opt to include the WMC duct in future models, the logic is hard to deny.

“A 10 per cent advantage from a range perspective is value that makes it worthwhile to adopt, and while there were some mechanical packaging challenges to deal with, like the rear shock and the rear subframes, the White Motorcycle Concepts team did a fantastic job in a very short time to work through those problems, and resolve them with the help of our engineers,” says Wismann. “So it’s got huge potential. If we can increase efficiency and range without adding more battery, what electric vehicle manufacturer wouldn’t want to do that?”

Put a pin in it

On March 6 at the “Design and Performance in Motion” event in Turin, WMC and legendary Italian design house Pininfarina announced an exciting collaboration by revealing their first concept designs for two new street-focused roadsters. Pininfarina, known for shaping automotive history, has now turned its expertise to two-wheelers, proving its wind tunnel capabilities can revolutionise motorcycle design. With WMC’s structural aerodynamic duct at its core, this concept could redefine the future of motorcycles – blending speed, efficiency and stunning Italian style. “The duct concept has always been about improving efficiency no matter the fuel source,” Rob White said at the event. “But this collaboration has taken this to the next level, showing how the duct can provide functional performance as well as be an aesthetic feature for future motorcycles.”

SPECIFICATIONS

City Range

Standard SR/S – 259 km

WMC SR/S – 323 km

Highway Range

Standard SR/S – 132 km

WMC SR/S – 166 km

Combined Range

Standard SR/S – 175 km

WMC SR/S – 219 km

Peak torque 190Nm

Peak power 82 kW (110hp) @ 5000rpm

Top speed* 200km/h

*Current Zero SR/S model

Power pack maximum capacity 14.4 kWh

Typical cost to recharge $1.61

Charge time to 95% 4.0 hr 2.0 hr

with 6kw rapid charge option

1.3 hr 1.0 hr

Weight 229kg

Seat height 787 mm

Power pack warranty

5 years/ unlimited kilometres