Internal ducting to allow smaller, sleeker bodywork

With its first riders WSBK title under its belt, sales success for the S1000RR and M1000RR, and rumours swirling about a future entry to MotoGP BMW is well on its way to becoming a leading light in the performance bike market alongside the likes of Ducati. Recently we’ve seen a particular focus on aerodynamics from the brand – both with the production M1000RR and with a spate of patents that could hint at future MotoGP machines – and the latest one introduces the idea of internal airflow ducts to replicate the effect of ‘Gurney flaps’ on bodywork.

Gurney flaps first appeared on racing cars in the 1970s, with F1 driver and engineer Dan Gurney pioneering them, hence the name. They’re short protrusions set at right angles to the airflow, normally at the trailing edge of an aerofoil or wing. Although they jut directly into the airstream, giving the impression they’d increase drag, they actually have the opposite effect and reduce drag while increasing the effectiveness of the aerodynamic surface they’re attached to.

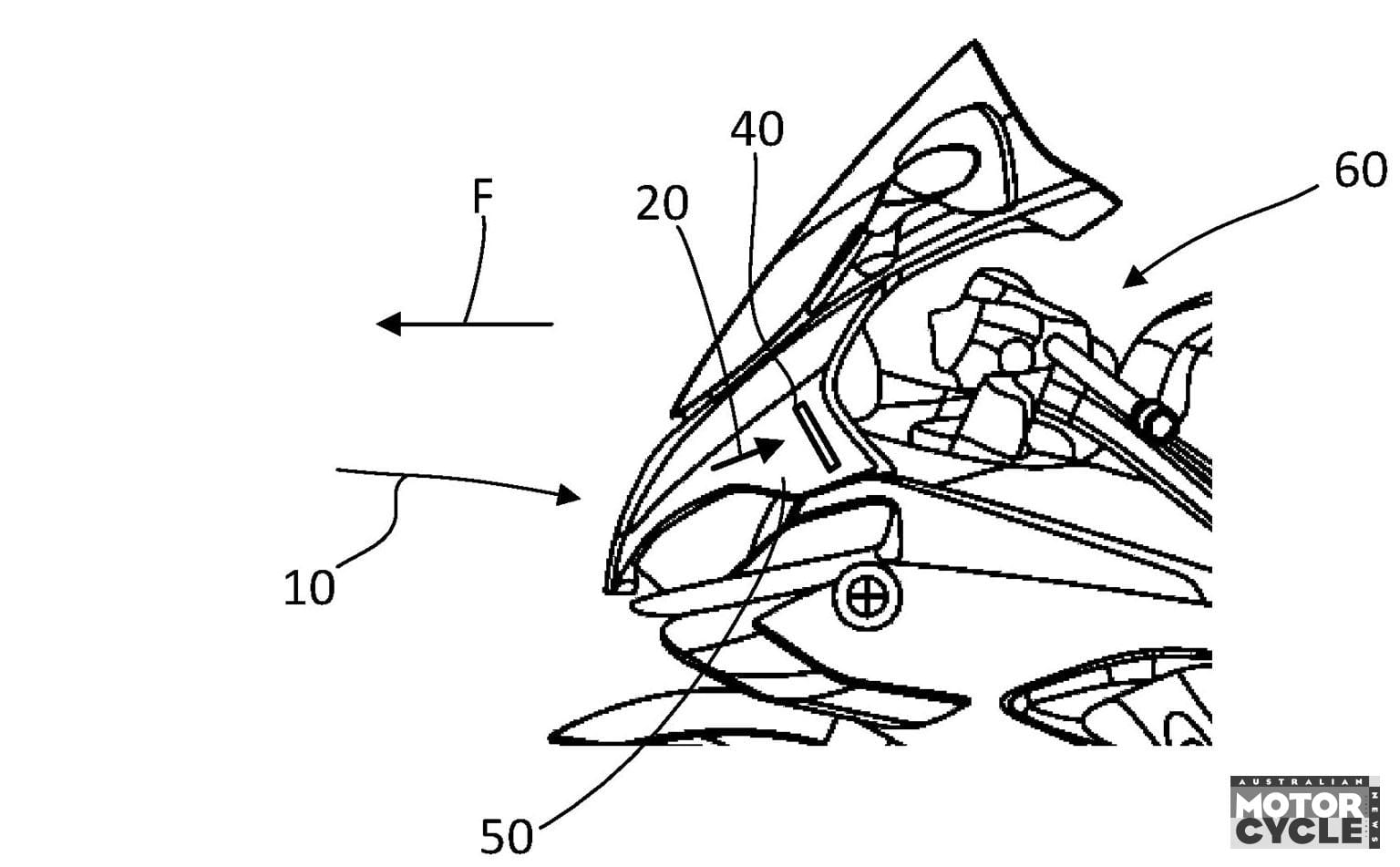

BMW’s idea is to replicate the effect of Gurney flaps without actually adding them. Instead it directs high-pressure air out through slots in the bodywork at around 90 degrees to the surface of the panel, using it to redirect the airflow away from the bodywork in the same way that a Gurney flap would.

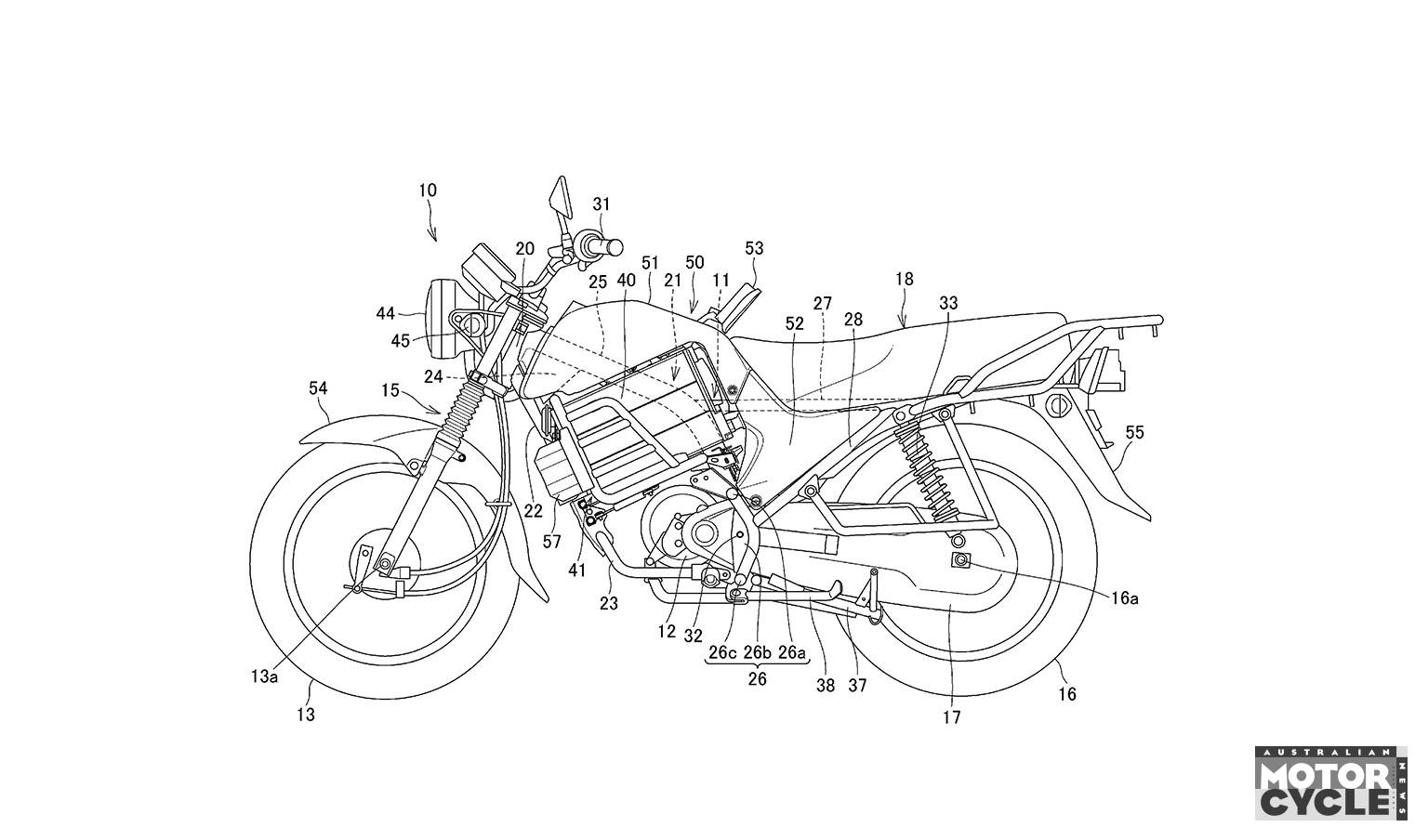

The patent application shows an S1000RR modified to adopt the idea. An intake set inside the bike’s main nose air duct scoops up high-pressure air and ducts it to slots on each side of the nose panel, just ahead of the handlebars. The result, according to the patent, is a front fairing that separates the airflow at its rearward edges more effectively and guides the air outward around the rider without requiring a larger area of bodywork or the addition of real Gurney flaps, which would less aesthetically pleasing.