Showa and Nissin join forces for cohesive brake and fork design

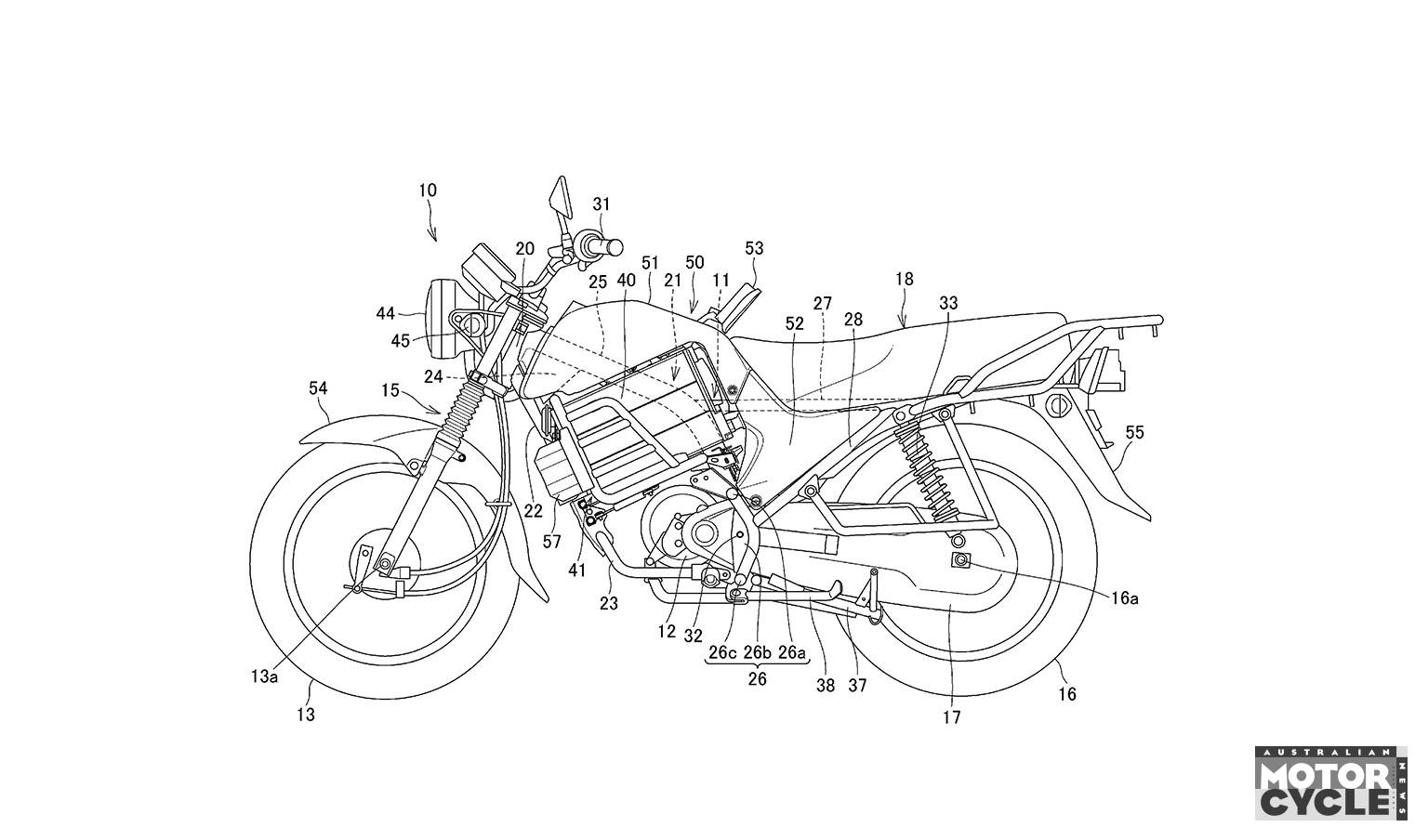

Astemo might not be a name you’re immediately familiar with but it’s a giant Japanese automotive supplier that’s parent to big motorcycling names Showa, Nissan and Keihin – putting it in an ideal position to take a holistic view of motorcycle components and leading to a recent patent showing how future forks can be designed to help with brake cooling.

What’s more, with Honda owning 40% of Astemo and with electronics brand Hitachi taking another 40%, designs from the company have a direct route into mainstream production, so we could see a system like this on showroom machines in the near future.

The idea is actually quite simple, building on a concept that was presented at last year’s EICMA show. At the event in November, Astemo showed a fork that bore both Showa and Nissin branding, with the brake calliper machined from the same single block of aluminium as the fork bottom. While that concept looked good, there are practical problems with the idea, not least the fact that it appears you’d have to remove the front wheel to swap the brake pads, and that the one-piece billet fork bottom and calliper would be expensive to make. On the plus side, it promised increased strength and the ability to efficiently absorb heat.

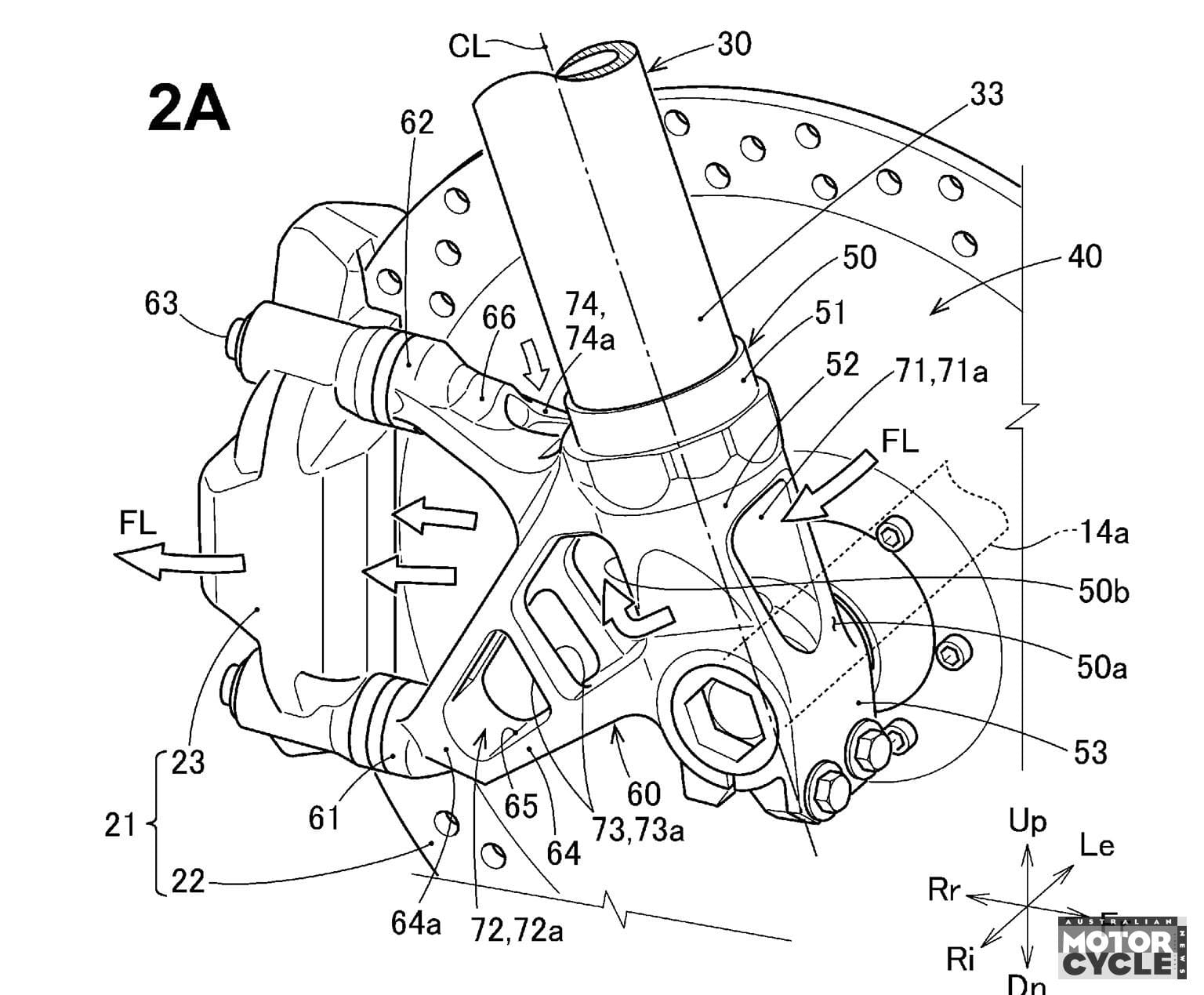

However, it also included another innovation – unmentioned in Astemo’s original press material – that has now reappeared in the company’s patent applications, and that’s a duct running through the fork bottom to direct cooling air straight onto the calliper.

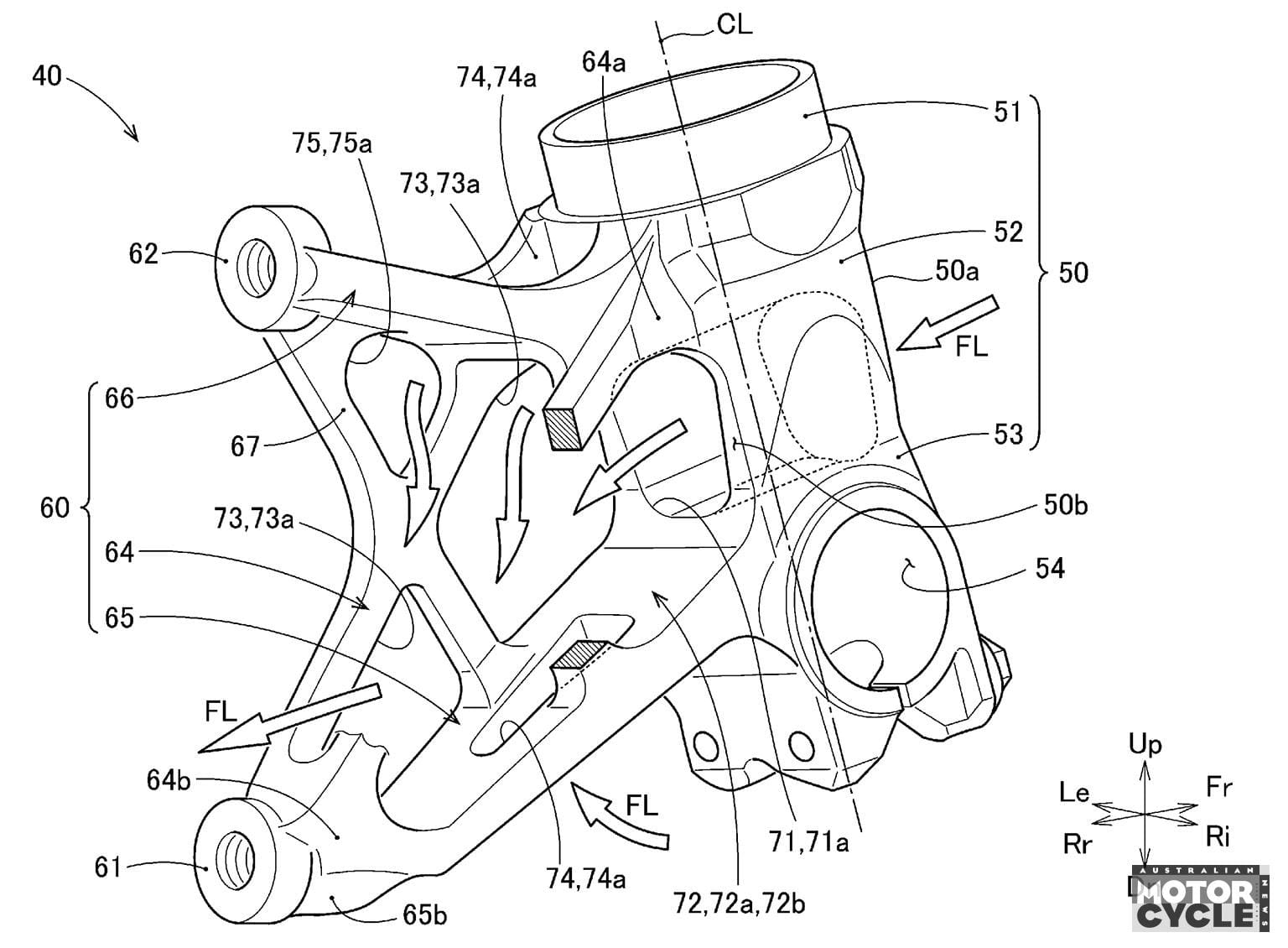

Astemo’s patent shows several variations on the idea, but all of them involve opening up the space between the bottom of the fork stanchion and the axle carrier, allowing air through the resulting gap. Any lost strength in the area is replaced in the form of a trellis-style design for the calliper bracket that also encourages more airflow.

Unlike the EICMA design concept, which also had that intake opening, the design in Astemo’s patent uses a conventional radial calliper, making it easy to swap components and performance maintenance jobs. Variations on the idea shown in the patent include the addition of another intake scoop or a vaned panel to direct air towards the calliper, as well as versions of the design that replace the hole-style duct at the bottom of the fork with a thin, blade-like structure that allows air to pass through the area.

Companies are putting an increased focus on brake cooling at the moment, as illustrated by the increasingly complex ducts and brake cowls appearing in MotoGP and on some production bikes like BMW’s M1000RR and CFMoto’s new 675SR-R. Adapting fork bottoms to improve that cooling ability is a logical next step, and one that Honda could have an advantage in thanks to its stake in Astemo.